In the fast-evolving wind energy sector, ensuring the reliability and efficiency of wind farm equipment is critical for operators and investors alike. Advanced monitoring solutions now play an essential role in addressing operational challenges, from unexpected downtime to maintenance planning. This article examines how wind equipment health monitoring enhances wind farm performance, leveraging advanced analytics and real-time data tools.

Why Monitor Wind Equipment Health?

Wind farms rely on complex machinery operating in demanding conditions, making equipment health a key factor for success. Unplanned outages or declining performance can lead to significant revenue losses and operational inefficiencies. Monitoring the health of wind turbines and related systems provides a proactive way to identify issues before they escalate, ensuring consistent energy production and mitigating risks.

The Impact of Downtime on Wind Farms

Downtime—whether caused by mechanical failures, weather events, or maintenance delays—directly affects a wind farm’s availability and profitability. Without precise data, operators struggle to identify root causes, which can lead to extended outages or disputes with service providers over responsibility. This lack of transparency undermines trust and complicates contract negotiations.

Benefits of Proactive Monitoring

By tracking equipment health, operators gain insights into performance trends and potential vulnerabilities. This enables timely interventions, such as scheduling maintenance during low-wind periods or ordering spare parts in advance. Ultimately, proactive monitoring improves wind farm efficiency and supports long-term operational stability.

How Wind Equipment Health Monitoring Works

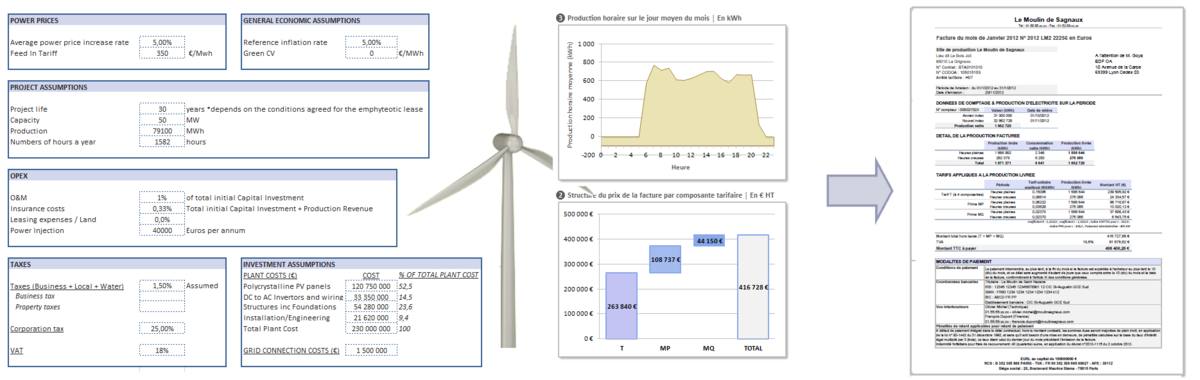

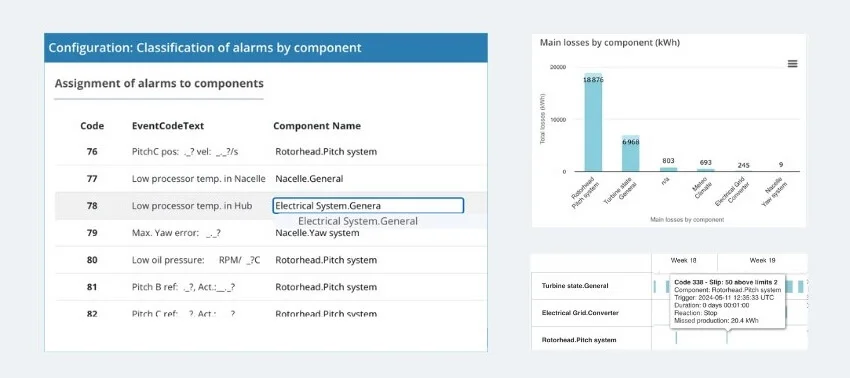

Modern wind farms rely on advanced software solutions that integrate with existing systems to deliver actionable insights. These tools analyze real-time data and performance metrics, offering a comprehensive view of equipment condition. SCADA data, combined with machine learning and statistical algorithms, can anticipate equipment failures with unprecedented accuracy.

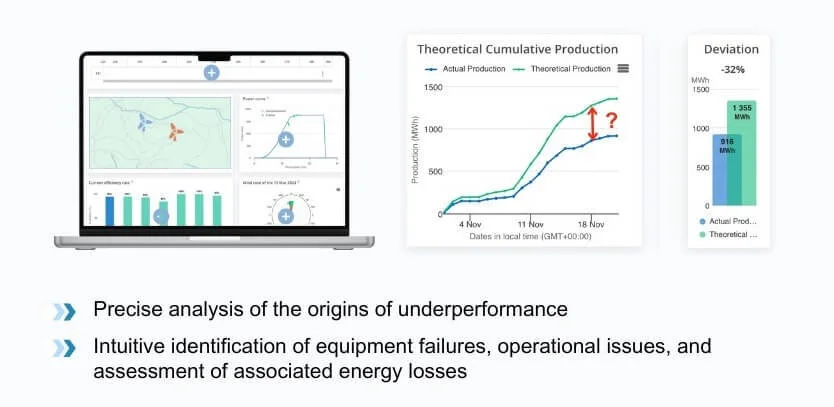

Real-Time Analytics for Immediate Insights

Ensuring the reliability of wind farm equipment is essential for operators seeking to improve efficiency and reduce costly downtime. Solutions based on real-time analytics provide immediate visibility into equipment status, enabling rapid responses to potential failures. This capability is critical for maintaining operational continuity and maximizing energy output.

Data Analytics Solutions for Deeper Understanding

Advanced data analytics solutions go beyond basic monitoring. By integrating with SCADA systems and other data sources, these tools track key performance indicators such as vibration, temperature, and power output, delivering performance analytics tailored to each turbine. This detailed analysis helps operators identify inefficiencies and prioritize corrective actions effectively.

Smarter Wind Turbine Maintenance

Effective wind turbine maintenance depends on accurate data for proactive action. Software with real-time data analysis capabilities processes live data streams, providing recommendations that optimize maintenance schedules. For example, detecting a worn bearing early can prevent a costly failure, extending equipment life and improving reliability.

Case Study: Enhancing Wind Farm Efficiency

A mid-sized wind farm faced recurring downtime due to equipment wear. Operators adopted a specialized monitoring solution to address these challenges and improve overall performance, demonstrating the practical benefits of advanced tools in real-world operations.

The Challenge

The wind farm struggled with inconsistent availability, as unexpected turbine failures caused prolonged outages. Without reliable data, assigning responsibility—whether to equipment issues or service delays—became contentious, complicating operational planning and financial forecasts. These recurring issues also raised concerns among stakeholders, eroding trust and confidence.

The Solution

A wind equipment health monitoring platform was deployed, integrating seamlessly with the farm’s SCADA system. The solution used performance analytics to track equipment health in real time, categorizing incidents by cause and severity. Operators accessed an intuitive dashboard to visualize downtime sources—such as mechanical wear or external factors—and adjust maintenance priorities accordingly, streamlining decision-making.

The Outcome

The monitoring system transformed the wind farm’s operations. By applying performance analytics and real-time monitoring, downtime was reduced by 20% within six months. Maintenance shifted from reactive to predictive, cutting repair costs and increasing wind farm efficiency. The data-driven approach also strengthened relationships with service providers by aligning all parties on transparent performance metrics, fostering better collaboration.

The Strategic Value of Equipment Health Monitoring

Wind equipment health monitoring is more than a technical tool—it is a strategic asset for operators. By combining advanced analytics with practical insights, these solutions help optimize maintenance, extend equipment life, and ensure consistent performance across fleets. During due diligence for wind farm acquisitions or refinancing, health monitoring data offers a transparent view of asset reliability, enabling investors to assess historical performance and maintenance practices, thereby reducing risk and improving valuation models. For long-term performance, anticipating and addressing equipment issues supports sustained improvements, aligns operations with efficiency goals, and ensures wind farms deliver maximum value over their lifecycle.

Learn more about WindDeep’s Health Monitoring Software and how it improves wind farm performance.